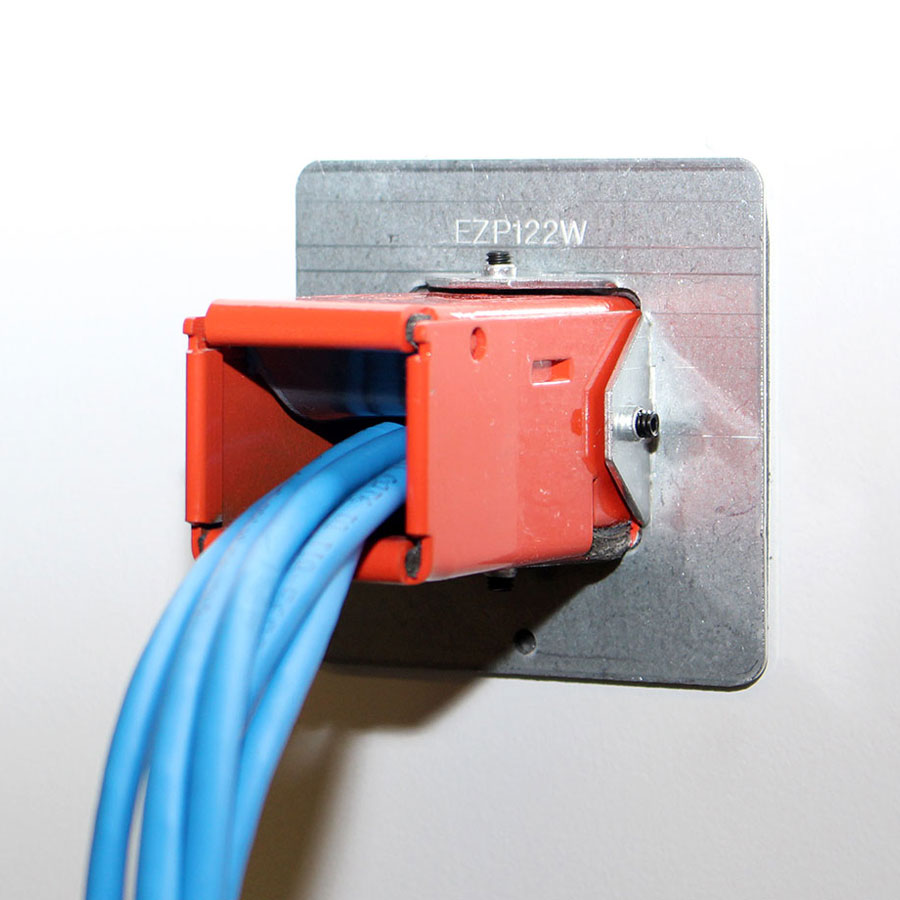

Firestop Pillows are designed for firestopping medium to large openings

containing various penetrating items such as pipes, conduits, cables,

insulated metal pipes, bus ducts and HVAC ducts. Pillows are

particularly well suited for applications involving data,

communications, power or control cables, innerducts and cable trays.

This method of sealing offers easy retrofitting of cable installations

without the need to damage the firestop seal. Difficult applications

such as one-sided shaft wall installations and other applications where

access is restricted to one side of the assembly may be easily

firestopped with this material.